Apabila anda mula merancang projek anda, anda ingin memastikan anda memilih yang betul Profil Aluminium Tersuai . Pertama, fikirkan tentang keperluan projek anda. Langkah ini membantu anda mengelakkan kesilapan di kemudian hari. Tanya diri anda apakah permohonan itu. Pertimbangkan berapa berat profil mesti menyokong dan jenis persekitaran yang akan dihadapinya.

Anda boleh memilih aloi dan bentuk aluminium terbaik apabila anda mengetahui keperluan anda.

Sokongan berat dan keadaan persekitaran penting dalam pilihan anda.

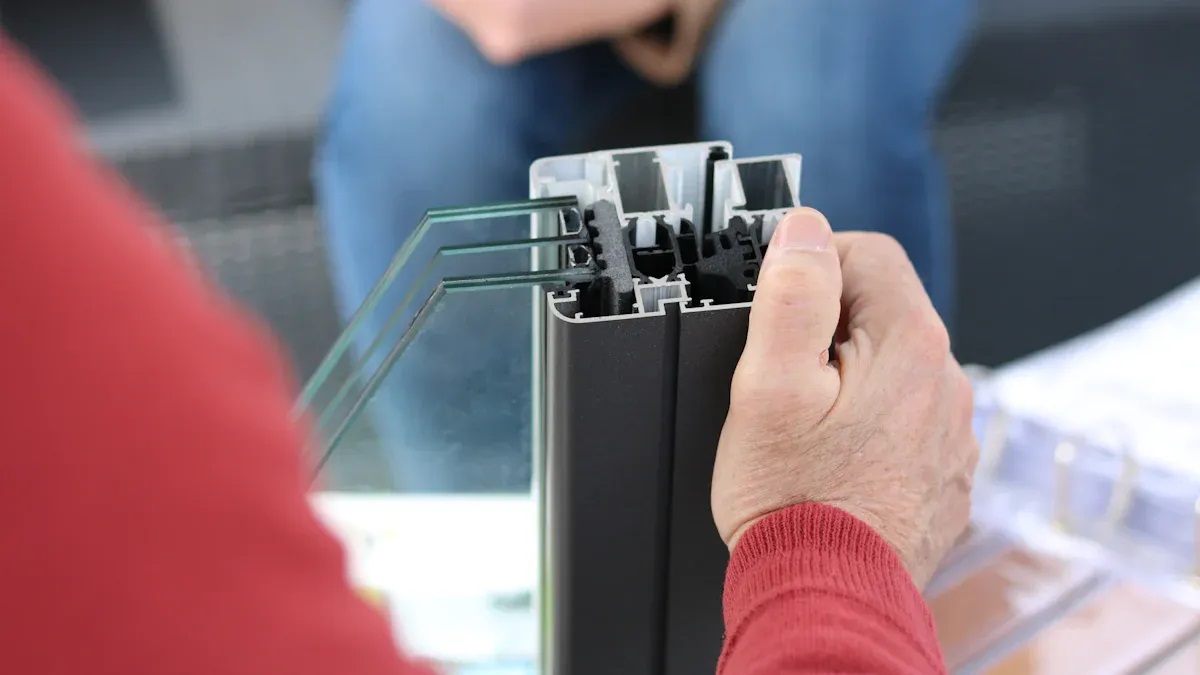

Pengukuran yang tepat, seperti ketebalan dinding dan keratan rentas, memastikan semuanya sesuai dan berfungsi dengan baik.

Mengambil masa untuk memikirkan perkara ini menjadikan proses selebihnya lebih mudah.

Fikirkan tentang keperluan projek anda sebelum anda memilih profil aluminium tersuai. Lihat bagaimana anda akan menggunakannya, berapa berat yang mesti dipegang, dan di mana ia akan digunakan.

Pilih aloi aluminium dan bentuk profil terbaik untuk berat yang perlu dibawa. Aloi mempunyai tahap kekuatan yang berbeza dan bertahan untuk masa yang berbeza.

Ukur ketebalan dinding dan keratan rentas dengan teliti supaya ia sesuai dengan baik. Ini membantu menghentikan masalah apabila anda memasangnya.

Pilih kemasan permukaan yang betul untuk menjadikan profil tahan lebih lama dan kelihatan lebih baik. Anodizing dan salutan serbuk adalah pilihan biasa.

Semak pembekal dengan melihat cara mereka memastikan produk mereka bagus dan cara mereka membantu dengan pesanan tersuai. Pembekal yang baik boleh membantu projek anda berjalan dengan baik.

Sebelum anda memilih profil aluminium tersuai, fikirkan tentang keperluan projek anda. Langkah ini membantu anda mengelakkan masalah kemudian. Mari lihat apa yang perlu anda pertimbangkan.

Tanya diri anda, "Untuk apa saya akan menggunakan profil ini?" Jenis aplikasi mempengaruhi setiap pilihan yang anda buat seterusnya. Adakah anda membuat bingkai untuk mesin, rak atau sebahagian daripada bangunan? Setiap penggunaan ada keperluan tersendiri.

Berikut ialah pandangan ringkas di mana profil aluminium tersuai digunakan:

|

Kawasan Permohonan |

Penerangan |

|---|---|

|

Automasi Perindustrian |

Digunakan dalam mesin yang bergerak sendiri dan di kilang. |

|

Aplikasi Struktur |

Bingkai untuk kereta, produk dan bangunan hijau. |

|

Pengurangan Berat |

Dipilih apabila anda memerlukan bahagian yang kuat tetapi ringan. |

|

Peralatan Mekanikal |

Ditemui dalam tali pinggang penghantar, pengangkat dan mesin ujian. |

|

Perlindungan Keselamatan |

Melindungi orang dan peralatan di kawasan kerja yang sibuk. |

Anda boleh menemui profil ini di sekolah dan hospital. Ia juga digunakan dalam bangunan di mana reka bentuk dan fungsi penting. Profil aluminium tersuai membolehkan anda memilih bentuk dan saiz yang anda mahukan. Anda boleh memilih sesuatu yang kelihatan hebat atau sesuatu yang sangat kuat.

Petua: Fikirkan betapa mudahnya untuk memasukkan dan membetulkan profil anda. Sesetengah profil aluminium membuat perubahan dan pembaikan lebih mudah.

Seterusnya, tentukan berapa berat yang perlu dipegang oleh profil anda. Sesetengah projek memerlukan profil yang boleh memuatkan benda berat. Yang lain hanya memerlukan sesuatu yang ringan dan mudah untuk bergerak. Kekuatan yang anda perlukan akan membantu anda memilih aloi dan reka bentuk yang betul.

Berikut ialah beberapa contoh berapa banyak profil berat boleh disimpan:

Profil aluminium industri 2020 boleh memuatkan kira-kira 20KG.

Jika anda menambah lebih banyak sokongan, profil yang sama itu boleh menampung sehingga 40KG.

Profil 4545, 500mm panjang, boleh mengambil beban 800N dengan sedikit lenturan.

Jenis profil aluminium yang anda pilih amat penting. Aloi membuat perbezaan yang besar. Contohnya, 6063 bagus untuk kebanyakan kerja, tetapi 6061 lebih baik untuk kerja berat. Sentiasa padankan bentuk dan saiz profil dengan berat yang diperlukan oleh projek anda.

Nota: Jika anda tidak pasti, minta bantuan pembekal anda. Mereka boleh membantu anda memilih profil yang sesuai untuk keperluan anda.

Sekarang, fikirkan tentang di mana anda akan menggunakan profil aluminium anda. Adakah ia berada di luar semasa hujan, berhampiran udara masin, atau di sekitar bahan kimia? Persekitaran boleh mengubah tempoh profil anda bertahan dan sejauh mana ia berfungsi.

Berikut ialah jadual untuk menunjukkan cara perkara yang berbeza mempengaruhi profil aluminium:

|

Faktor |

Kesan pada Profil Aluminium |

|---|---|

|

Suhu |

Haba yang tinggi boleh menyebabkan kakisan berlaku lebih cepat, terutamanya berhampiran lautan. |

|

Kelembapan |

Air yang banyak di udara boleh merosakkan lapisan pelindung dan menyebabkan keretakan. |

|

Pendedahan Bahan Kimia |

Bahan kimia seperti klorida boleh merosakkan logam dan menjadikannya tahan lebih lama. |

Jika anda menggunakan profil anda di luar atau di tempat yang sukar, anda mungkin memerlukan salutan atau anodisasi khas. Ini membantu melindungi daripada karat dan kerosakan. Di tempat yang mempunyai banyak garam atau pencemaran, langkah ini adalah lebih penting.

Ingat: Kemasan permukaan yang betul boleh memastikan profil anda kelihatan baik dan berfungsi dengan baik untuk masa yang lama.

Apabila anda meluangkan masa untuk memikirkan aplikasi, beban dan persekitaran anda, anda bersedia untuk berjaya. Lebih mudah untuk memilih jenis profil aluminium yang betul, bentuk dan saiz profil terbaik, dan kemasan yang sesuai untuk projek anda.

Apabila anda melihat profil aluminium, anda mempunyai dua pilihan. Satu ialah profil standard. Yang lain ialah profil tersuai. Profil standard sesuai dengan kebanyakan projek. Mereka datang dalam pelbagai bentuk dan saiz. Anda boleh mendapatkannya dengan mudah. Pilihan profil aluminium tersuai membolehkan anda membuat sesuatu yang istimewa. Anda mungkin memerlukan bentuk baharu atau lebih kekuatan.

Berikut ialah jadual untuk membantu anda membandingkan:

|

Faktor |

||

|---|---|---|

|

Keperluan Permohonan |

Dibuat untuk reka bentuk yang kompleks |

Baik untuk kegunaan umum |

|

Kecekapan Kos |

Kos lebih pada mulanya untuk reka bentuk dan alatan |

Lebih murah dan mudah didapati |

|

Masa Utama Pengeluaran |

Mengambil masa lebih lama untuk dibuat |

Sedia untuk digunakan dengan cepat |

|

Kekuatan & Ketahanan Bahan |

Aloi khas dan kekuatan tambahan mungkin |

Kuat tetapi tidak banyak perubahan dibenarkan |

|

Fleksibiliti Reka Bentuk |

Bentuk dan ciri yang unik |

Tetapkan saiz dan bentuk |

Jika projek anda memerlukan sesuatu yang istimewa, pilih profil aluminium tersuai. Untuk kerja mudah, profil standard menjimatkan masa dan wang.

Profil aluminium terdapat dalam pelbagai bentuk dan saiz. Anda boleh memilih bentuk pepejal seperti segi empat sama, segi empat tepat, bulat atau heksagon. Bentuk berongga juga biasa. Ini termasuk tiub dan saluran. Berikut ialah beberapa jenis yang mungkin anda lihat:

Tiub berongga

Lubang persegi

Lubang segi empat tepat

Paip struktur

Saluran aluminium

saya-rasuk

Sudut

Tee

Zees

Bar

Setiap bentuk memberikan profil aluminium anda kekuatan yang berbeza. I-beam membantu dengan beban yang berat. T-slot membolehkan anda membina bingkai yang boleh anda ubah kemudian. Bentuk dan saiz yang betul menjadikan profil anda kukuh dan selamat.

|

Jenis Profil |

Penerangan |

Kesan terhadap Integriti Struktur |

|---|---|---|

|

I-Beams |

Digunakan dalam membina untuk kekuatan. |

Pegang berat yang besar dan tingkatkan kapasiti beban. |

|

T-Slot |

Baik untuk bingkai yang anda boleh laraskan. |

Jadikan reka bentuk fleksibel dan berfungsi dengan lebih baik. |

Anda mahu sistem profil aluminium anda berfungsi dengan aksesori yang betul. Keserasian yang baik membolehkan anda menambah kurungan, penyambung, penutup hujung, engsel, peluncur dan pengikat dengan mudah. Bahagian ini membantu anda membina dan menyambungkan profil anda.

kurungan

Penyambung

Tudung akhir

Engsel

Peluncur

Pengikat

Meratakan kaki

Sendi sudut

Aksesori sesuai dengan banyak saiz seperti profil siri 20, 30, 40, 45, 60 dan 80. Sentiasa semak sama ada ia sepadan sebelum anda membeli. Padanan yang betul memastikan sistem anda selamat dan stabil. Jika anda salah memilih saiz, anda mungkin menghadapi masalah semasa membina. Pilih aksesori yang diperbuat daripada bahan yang kuat untuk sokongan yang lebih baik.

Petua: Sentiasa padankan saiz aksesori dengan profil aluminium anda. Langkah ini menjadikan projek anda lebih mudah dan selamat.

Memilih bahan dan kemasan yang betul adalah penting. Ia boleh mengubah cara projek anda kelihatan dan berfungsi. Mari lihat apa yang anda patut tahu.

Terdapat beberapa gred aluminium biasa untuk profil tersuai. Setiap satu mempunyai kegunaan dan kekuatan terbaiknya sendiri.

6061 banyak digunakan dalam bangunan dan kilang.

6063 bagus untuk kerja yang serupa dan mudah dibentuk.

Berikut ialah jadual untuk membantu anda membandingkan:

|

Gred Aluminium |

Kekuatan Tegangan (MPa) |

Rintangan Kakisan |

Kos (setiap kg) |

|---|---|---|---|

|

5052 |

220 |

Cemerlang, terutamanya dalam air masin |

$1.50 - $3 |

|

6061 |

310 |

Baik, digunakan secara meluas dalam struktur |

$1.50 - $3 |

|

7075 |

572 |

Tahan terhadap bahan kimia dan keadaan yang keras |

$1.50 - $3 |

Jika anda memerlukan sesuatu yang sangat kuat, pilih 7075. Untuk kebanyakan kerja membina, 6061 atau 6063 akan berfungsi dengan baik.

Kemasan yang anda pilih mengubah cara profil aluminium anda kelihatan dan tahan lama. Beberapa kemasan menghentikan karat. Yang lain membuat logam berkilat.

|

Kemasan Permukaan |

Faedah |

|---|---|

|

Kemasan Kilang |

Murah dan mudah; tidak kelihatan cantik; tidak bertahan lama. |

|

Anodizing |

Menghentikan karat dan haus; membantu dengan haba; boleh tambah warna. |

|

Salutan Serbuk |

Banyak warna; kuat dan sukar; baik untuk di luar. |

|

Alodining |

Lebih murah daripada anodizing; menghentikan karat; mengekalkan aliran elektrik. |

|

Mencelup Terang |

Menjadikan logam sangat berkilat. |

|

Kemasan Mekanikal |

Menjadikan permukaan licin; menyediakannya untuk kemasan lain. |

Kemasan yang betul membantu profil anda bertahan lebih lama dan kelihatan lebih baik. Anodisasi boleh menjadikan aluminium anda bertahan selama bertahun-tahun. Salutan serbuk memberi warna dan mudah dijaga. Jika anda salah memilih kemasan, profil anda mungkin tidak kekal atau kelihatan baik.

Petua: Fikirkan tentang berapa lama anda mahu profil aluminium anda bertahan. Juga, fikirkan tentang di mana anda akan menggunakannya sebelum anda memilih kemasan.

Anda mahu projek anda kelihatan bagus dan berfungsi dengan baik. Kadang-kadang anda perlu memilih antara dua perkara ini. Berikut adalah beberapa petua:

Profil aluminium membolehkan anda membuat reka bentuk yang menarik dan masih berfungsi dengan baik.

Profil yang kukuh memastikan projek anda selamat dalam cuaca buruk atau penggunaan berat.

Kemasan istimewa boleh menjadikan projek anda kukuh dan bergaya.

Ramai arkitek menyukai bahan yang boleh memuatkan banyak idea.

|

Aspek |

Estetika |

Kefungsian |

|---|---|---|

|

bahan |

Aluminium kelihatan bagus |

Kuat dan menjimatkan tenaga |

|

Fleksibiliti Reka Bentuk |

Membolehkan anda membuat reka bentuk kreatif |

Sesuai dengan keperluan projek anda |

|

Kelestarian |

Boleh dikitar semula |

Tahan lama |

Bahan dan kemasan yang anda pilih akan mengubah rupa projek anda dan betapa kuatnya projek anda. Cuba cari pilihan yang sesuai dengan keperluan dan bajet anda.

Apabila anda merancang projek anda, anda ingin memastikan kos dan belanjawan anda terkawal. Memilih profil aluminium tersuai yang betul bermakna melihat lebih daripada sekadar tanda harga. Anda perlu memikirkan perkara yang mempengaruhi kos, tempoh masa yang diperlukan untuk mendapatkan pesanan anda, dan jika terdapat sebarang peraturan pesanan minimum.

Banyak perkara boleh mengubah kos profil aluminium anda. Berikut ialah jadual untuk membantu anda melihat perkara yang paling penting:

|

Faktor |

Penerangan |

|---|---|

|

Bursa Logam London |

Harga aluminium berubah setiap hari berdasarkan pasaran. |

|

Saiz Profil |

Profil yang lebih besar atau lebih kecil boleh menelan kos yang lebih tinggi untuk dibuat. |

|

Kos Mati |

Membuat cetakan baharu untuk bentuk anda menambah kos sekali sahaja. |

|

Berat per Meter |

Profil yang lebih berat menggunakan lebih banyak logam, jadi ia lebih mahal. |

|

Pandai Reka Bentuk |

Reka bentuk pintar boleh menjimatkan wang dengan mengurangkan kerja tambahan. |

|

Saiz Pesanan |

Pesanan yang lebih besar biasanya bermakna kos yang lebih rendah bagi setiap helai. |

|

Kos Penamat |

Kemasan istimewa seperti salutan serbuk atau anodisasi menambah kos. |

Jenis bahan yang anda pilih juga mengubah kos. Sesetengah aloi lebih mudah digunakan dan lebih murah. Jika reka bentuk anda rumit, ia mungkin memerlukan lebih banyak masa dan alat khas, yang boleh meningkatkan kos. Memesan lebih banyak keping sekaligus boleh membantu menurunkan harga untuk setiap satu.

Anda ingin tahu berapa lama masa yang diambil untuk mendapatkan profil anda. Bentuk tersuai mengambil masa lebih lama kerana kilang perlu membuat alat baharu. Profil standard adalah lebih pantas kerana ia sedia untuk digunakan. Berikut ialah pandangan ringkas tentang tempoh masa beberapa profil diambil:

|

Jenis Profil |

Masa Utama (Minggu) |

|---|---|

|

Tiub aluminium lancar yang dilukis |

50-60 |

|

Penyemperitan struktur dalam aloi 7xx & 2xx |

25-30 |

|

Tiub porthole yang dilukis |

12-14 |

Profil tersuai memerlukan masa tambahan untuk reka bentuk dan persediaan. Membuat die boleh mengambil masa 2-4 minggu. Jika bentuk anda kompleks, ia mungkin mengambil masa yang lebih lama. Sentiasa merancang lebih awal supaya projek anda kekal di landasan yang betul dan mengikut kos dan belanjawan anda.

Petua: Tanya pembekal anda tentang masa utama sebelum anda memesan. Ini membantu anda mengelakkan kelewatan.

Sesetengah pembekal mempunyai peraturan tentang jumlah yang anda perlu beli. Sebagai contoh, Profall meminta sekurang-kurangnya 200 kg setiap pesanan. Sesetengah syarikat membenarkan anda memesan lebih sedikit, yang bagus untuk projek kecil atau prototaip.

|

Pembekal |

Kuantiti Pesanan Minimum |

Masa Penghantaran |

|---|---|---|

|

Profall |

200 kg |

2 minggu |

|

Penyemperitan Aluminium |

Tiada minimum yang ketat |

T/A |

|

Chalco Aluminium |

T/A |

T/A |

Jika anda hanya memerlukan beberapa helai, cari pembekal tanpa pesanan minimum. Dengan cara ini, anda menjimatkan wang dan mengelakkan stok tambahan yang anda tidak perlukan. Untuk projek besar, pesanan yang lebih besar boleh membantu anda mendapatkan harga yang lebih baik.

Ingat: Mengimbangi kualiti dan kos serta belanjawan anda membantu projek anda berjaya. Sentiasa semak butiran sebelum anda membeli.

Memilih pembekal yang betul adalah sangat penting. Pembekal yang anda pilih boleh membantu projek anda atau menyebabkan masalah. Anda mahukan rakan kongsi yang mementingkan kualiti dan membantu dengan keperluan tersuai. Mereka juga harus membantu anda mengelakkan kesilapan. Berikut adalah perkara yang perlu diperiksa sebelum anda membuat keputusan.

Anda mahu projek anda bertahan lama. Sentiasa bertanya bagaimana pembekal menyemak kualiti. Pembekal yang baik menyemak kualiti pada setiap langkah. Mereka melihat bahan mentah dan menonton proses penyemperitan. Mereka juga menguji produk siap. Cari langkah ini:

Pemeriksaan bahan mentah

Kawalan proses penyemperitan

Semakan dimensi profil

Penilaian kualiti permukaan

Ujian sifat mekanikal

Pemeriksaan pembungkusan akhir

Langkah-langkah ini membantu memastikan profil aluminium anda bagus. Jika pembekal melangkau sebarang langkah, projek anda mungkin menghadapi masalah.

Setiap projek adalah berbeza. Anda mungkin memerlukan profil atau ciri khas. Pembekal yang baik membantu dengan reka bentuk dan kejuruteraan. Mereka juga membantu dengan kawalan kualiti. Sokongan penyesuaian yang kukuh membantu projek anda dalam pelbagai cara.

|

Ukuran Kawalan Kualiti |

Kesan terhadap Hasil Projek |

|---|---|

|

Pemilihan Bahan yang Tegas |

Memastikan profil anda kukuh dan tahan lama. |

|

Reka Bentuk dan Kejuruteraan Termaju |

Membantu mengesan masalah sebelum pengeluaran bermula. |

|

Pembuatan Ketepatan Tinggi |

Pastikan profil anda sepadan dengan reka bentuk anda dengan tepat. |

|

Kawalan Kualiti Dalam Proses |

Menangkap kesilapan lebih awal, jadi anda mendapat jenis profil aluminium yang betul. |

|

Ujian Pasca Pengeluaran |

Semak bahawa profil anda memenuhi semua keperluan kualiti. |

|

Kerjasama Pelanggan |

Membolehkan anda menyediakan rancangan tersuai untuk kejayaan projek anda. |

Bekerjasama dengan pembekal yang menawarkan penyesuaian yang kukuh menjadikan perkara lebih mudah. Projek anda akan menjadi lebih lancar dan menjadi lebih baik.

Sebelum anda memilih pembekal, gunakan senarai semak ini. Ia membantu anda membuat pilihan yang baik:

Adakah pembekal mempunyai proses kualiti yang kukuh?

Bolehkah mereka mengendalikan keperluan tersuai anda?

Adakah mereka membantu selepas jualan?

Adakah masa penghantaran dan pesanan minimum mereka sesuai untuk anda?

Adakah mereka mempunyai pengalaman dengan projek seperti anda?

Petua: Minta sampel atau rujukan daripada projek lain. Ini membantu anda melihat sama ada kualiti mereka adalah baik.

Ramai orang membuat kesilapan yang sama semasa memilih profil. Berikut adalah beberapa kesilapan biasa dan cara mengelakkannya:

|

Kesilapan |

Penerangan |

|---|---|

|

Memilih standard yang salah |

Mencampurkan piawaian Cina dan Eropah boleh membawa kepada profil yang salah untuk projek anda. |

|

Mengabaikan kapasiti galas beban |

Tidak menyemak jumlah berat yang perlu dipegang oleh profil anda boleh menyebabkan masalah besar. |

|

Gagal membezakan jenis |

Memilih profil yang ringan untuk kerja berat bermakna projek anda mungkin tidak selamat atau cukup kuat. |

Untuk mengelakkan kesilapan ini, sentiasa:

Semak toleransi awal dan berbincang dengan pakar jika perlu.

Gunakan sudut bulat dan bukannya sudut tajam untuk penyemperitan yang lebih baik.

Reka bentuk profil yang mudah disatukan.

Cuba buat reka bentuk anda seimbang dan sekata.

Jika anda mengikuti langkah ini, anda akan memilih profil aluminium yang betul. Projek anda akan mempunyai peluang yang lebih baik untuk berjaya.

Anda kini tahu cara memilih profil aluminium tersuai yang betul untuk projek anda. Mulakan dengan memikirkan keperluan anda. Lihat pada aplikasi, beban dan persekitaran. Pilih gred aluminium terbaik dan kemasan untuk kerja anda. Pastikan profil aluminium anda menepati bajet anda. Bercakap dengan pembekal atau pakar jika anda mempunyai soalan. Mereka boleh membantu anda mendapatkan profil aluminium tersuai yang sempurna. Bersedia untuk memulakan? Hubungi hari ini untuk mendapatkan maklumat lanjut atau sokongan!