Table of Contents

To help you better navigate this article, here’s a quick overview of the main sections:

Architectural aluminium profile types are strong and flexible for new buildings. 6063 aluminum looks very smooth. 6061 and 6005 aluminum are stronger. Profiles have many shapes like L, T, and modular. Each architectural aluminium profile helps with special building or design needs.

Picking the right aluminum profiles for a project—like weight, look, and weather—makes sure it works well and lasts long.

-

Architectural aluminium profile with anodized or plain finishes can look nice and help the environment.

-

Designers and builders pick profiles for how they will be used, thinking about strength, style, and care.

Key Takeaways

-

Architectural aluminum profiles are strong and light. They let builders make many designs for new buildings. - Picking the right alloy and finish is important. 6063 looks nice, and 6061 is very strong. This helps the building last long and look good. - T-slot and v-slot profiles help make strong frames. They also help parts move smoothly. These profiles fit many project needs. - Anodized finishes keep aluminum safe from weather and scratches. They also give more color and style choices. - Work with good suppliers and plan your project well. This helps you get the best aluminum profiles that last a long time.

Why Use Architectural Aluminium Profile

Benefits in Modern Design

Architectural aluminium profile gives many good things for new buildings. Architects like aluminum because it is strong and light. It is also easy to use for different shapes. This material lets people make cool designs and special ideas. Aluminum profiles help make thin frames and big glass walls. These things help rooms look open and bright.

Aluminum does not rust easily. It makes a layer that keeps water and weather out. This helps it last a long time inside or outside. Aluminum lasts longer than wood, even when it rains a lot.

Architects like aluminum because it is good for the planet. You can recycle it again and again. It does not get weaker after recycling. This helps save resources and makes less trash. Aluminum profiles can do more than one job, like hiding wires or holding screws. This makes building easier and saves money.

Here are some reasons architects pick aluminum instead of steel or wood:

-

Aluminum is much lighter than steel, so buildings weigh less.

-

It does not rust like steel.

-

It is strong for its weight, so it is tough but not heavy.

-

Aluminum is easy to cut and shape for special designs.

-

It lasts longer than wood, especially outside.

-

You can recycle it many times.

-

Special profiles can help make building faster.

Common Applications

Architectural aluminium profile works for many things in new buildings. Builders use these profiles for windows, doors, and walls. They also use them for railings, sunshades, and decorations. Many architects use aluminum extrusions for room dividers and inside walls.

Aluminum profiles help with both strong and pretty parts of buildings. They are used in frames that hold weight, light walls, and even furniture. Aluminum is easy to use for many designs in homes and offices. Manufacturers make many shapes and colors, so it fits any style.

People use aluminum more as they want strong, green, and nice-looking materials. Because it works for so many things, architectural aluminium profile is a top pick for new buildings.

Types of Architectural Aluminium Profile

Standard Profiles (L, T, Structural)

Architectural aluminium profile comes in shapes like L, T, and beams. These profiles are important for many building jobs.

-

L-shaped profiles have two sides that meet at a corner. They make corners strong and do not rust easily. Builders use them for support, bracing, and trim.

-

T-shaped profiles, like t-slot aluminum profiles, help hold weight and connect parts. T-slot designs let you join pieces fast and change them easily.

-

Structural shapes, like I-beams and H-beams, give strong support. These profiles use alloys like 6061 and 6063 to stay strong and not rust.

-

Most standard profiles are made from 6061, 6063, or 1100 alloys. The wall thickness changes how much weight the profile can hold.

-

Standard extruded aluminum profiles are simple and easy to get. They work for many building and design needs.

Slim and Modular Profiles

Slim and modular profiles let architects try new ideas. These profiles make thin frames for windows and doors. They also work for walls and decorations.

T-slot aluminum profiles and v-slot aluminum profiles are used in modular systems. T-slot profiles have a groove for connectors and bolts. This makes building quick and easy to change.

V-slot aluminum profiles have a special groove shape. The v-slot lets wheels and sliders move smoothly. Builders use v-slot aluminum profiles for sliding doors, moving walls, and displays.

T-slot and v-slot aluminum profiles help with modular building. They make strong, light structures that can be changed when needed.

Anodized vs Raw Finishes

Picking anodized or raw finishes changes how profiles look and last.

-

Anodized aluminum has a thick, even layer on top. This layer keeps out water and chemicals. It makes the surface harder and stops scratches.

-

Anodized aluminum comes in many colors and styles. Designers can pick what looks best.

-

Clear anodized aluminum keeps the metal look but adds protection. Hard anodized aluminum is even stronger for tough jobs.

-

Anodized aluminum helps paint and coatings stick better. The surface gets tiny holes, which helps with looks and use.

-

The anodized layer does not let electricity pass through. Raw aluminum lets electricity flow, but anodized does not.

-

Anodized aluminum lasts longer outside and in wet places. It gives a tough finish that stands up to weather and use.

-

Raw aluminum has only a thin, uneven layer on top. It does not protect as well as anodized aluminum.

Anodized aluminum profiles give architects a tough finish and more style choices. They work better in rough places than raw profiles.

Key Alloys in Aluminum Extrusions

6063 for Architecture

6063 is the most used alloy for building aluminum profiles. This alloy makes surfaces look smooth and lines look sharp. Many architects pick 6063 for a modern style in windows, doors, and curtain walls. The alloy does not rust easily, so buildings last longer in bad weather.

6063 aluminum extrusions are strong and look nice. They are good for frames that do not need to hold much weight but must look great.

Manufacturers often say to use 6063 when style is very important. This alloy can get anodized finishes, which adds more protection and color choices. Builders use 6063 in aluminum profile systems for homes and offices.

6061 and 6005 for Strength

6061 and 6005 alloys are stronger for aluminum profiles. These alloys help make parts that must hold more weight. 6061 aluminum extrusion is used for beams, columns, and other heavy parts.

6061 is strong and easy to work with. It can hold heavy things and does not bend much. 6005 is even stronger, so it is used for big frames or factories.

|

Alloy |

Best For |

Load-Bearing Capacity |

Surface Finish |

|---|---|---|---|

|

6063 |

Windows, doors, facades |

Medium |

Very smooth |

|

6061 |

Beams, columns |

High |

Smooth |

|

6005 |

Large frames, supports |

Very high |

Good |

6061 and 6005 aluminum extrusions help make buildings safe and strong. Manufacturers suggest these alloys when a project needs to be tough and hold a lot of weight. These alloys also do not rust, so they last a long time in many places.

T-Slot vs V-Slot Aluminum Extrusion

Structural Differences

T-slot and v-slot aluminum extrusion are different in shape and use. T-slot aluminum extrusion has a T-shaped slot on one or more sides. This slot lets you fasten things tightly and move them if needed. V-slot aluminum extrusion has a V-shaped groove on all four sides. The V-shape helps wheels move smoothly in a straight line.

|

Feature |

V-slot Aluminum Extrusion |

T-slot Aluminum Extrusion |

|---|---|---|

|

Groove Shape |

V-shaped groove on all four sides |

T-shaped slot on one or more sides |

|

Primary Function |

Designed for linear motion with V-shaped wheels |

Designed for secure and adjustable fastening |

|

Typical Applications |

3D printers, CNC machines, automation systems |

Workbenches, enclosures, machine frames |

|

Modularity |

Modular and reconfigurable for precise positioning |

Modular framework allowing easy attachment of accessories |

|

Key Advantage |

Smooth, precise linear motion |

Flexibility, adjustability, and secure connections |

T-slot aluminum profiles are great for building strong frames. V-slot aluminum profiles are best for projects that need things to slide. Both types can hold a lot of weight. You should pick the one that fits your project’s needs for movement or strong connections.

Best Uses in Architecture

Architects use t-slot and v-slot aluminum extrusions for many jobs. T-slot aluminum extrusion is good for machine frames and workstations. It is also used for safety enclosures. These profiles are easy to put together and change without welding. V-slot aluminum profiles work well for sliding doors and moving walls. They are also used for display systems. The v-slot groove lets wheels roll easily, so things can move in a straight line.

-

Machine frames and bases use t-slot for strong support and balance.

-

Custom workstations use t-slot aluminum profiles for comfort and easy changes.

-

Automation systems and robots use both t-slot and v-slot aluminum extrusions for exact placement and easy changes.

-

Clean rooms and special spaces like v-slot aluminum extrusion for smooth surfaces and easy cleaning.

-

Safety guards and enclosures use t-slot for quick and strong building and changes.

Aluminum extrusions from good aluminium profile manufacturers are always high quality. Architectural aluminium profile systems often use both t-slot and v-slot aluminum extrusions for strength and movement. These profiles are strong, easy to change, and look neat, so they are a top pick for new building frames.

Tip: Pick t-slot or v-slot aluminum profile based on what your project needs. If you need strong connections, use t-slot. If you need smooth movement, use v-slot. Both types help architects make flexible, strong, and nice-looking spaces.

Profile Properties and Comparison

Strength and Durability

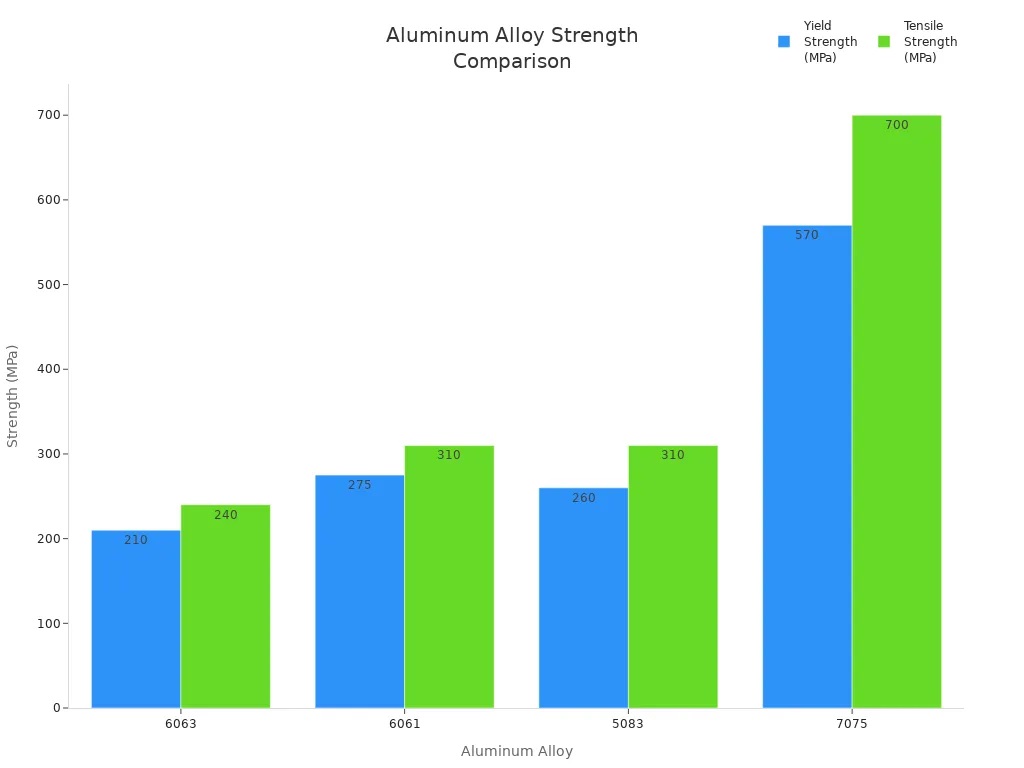

Architectural aluminium profile types have different strength and durability. The alloy, wall thickness, and shape change how strong a profile is. 6061 aluminum is stronger than 6063. This makes it better for frames and heavy parts. Many architects use 6063 because it looks smooth and does not rust. It is good for window and door frames. The table below shows how strong each alloy is:

|

Aluminum Alloy |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Typical Architectural Use |

|---|---|---|---|

|

6063 |

210 |

240 |

Commonly used for architectural applications, favored for aesthetics and corrosion resistance |

|

6061 |

275 |

310 |

Higher strength, suitable for structural components under load-bearing architectural elements |

|

5083 |

260 |

310 |

High strength and corrosion resistance, mainly for marine environments, less common in architecture |

|

7075 |

570 |

700 |

Very high strength, used in aerospace and military, generally not typical for architecture |

Thicker aluminum profiles can hold more weight and last longer. They do not bend easily and work well for big doors and curtain walls. Thinner profiles are lighter and let you make flexible designs. But they cannot hold as much weight. The right wall thickness gives good strength and long life. Aluminium profile manufacturers say to use thick profiles for frames. Thin profiles are better for decorations or modular parts.

T-slot and v-slot profiles both make strong connections. T-slot profiles are great for adjustable frames and workstations. V-slot profiles help things move smoothly, like sliding doors and moving walls. Both types work well if you pick the right alloy and thickness.

Appearance and Finish

How an architectural aluminium profile looks is important in design. Anodized aluminum has a tough finish and many color choices. Anodized profiles do not scratch or rust easily. They are good for inside and outside use. Many architects like anodized aluminum for its clean look and long-lasting surface.

Rougher surfaces protect better against rust. Ground-only finishes last longer than polished ones. This is because rough surfaces make a protective layer over time. Smooth surfaces with oxide films may not protect as well. Anodized finishes usually give the best results.

-

Anodized aluminum comes in many colors and styles, so it fits any design.

-

Anodized profiles have a hard, non-conductive surface that stands up to weather and use.

-

Anodized finishes help paint and coatings stick better, making them look and work better.

T-slot and v-slot profiles both look better with anodized finishes. T-slot profiles look nice in workstations and frames. V-slot profiles stay shiny and do not wear out in sliding systems. Anodized aluminum profiles are a top pick for architects who want style and function.

Cost and Maintenance

Cost and care depend on the alloy, finish, and profile type. 6063 aluminum profiles usually cost less than 6061. This is because they use less material and focus on looks. T-slot and v-slot profiles are easy to change, which saves money when building or fixing things. Anodized aluminum costs more at first, but it needs less care later.

-

Anodized aluminum profiles need less cleaning and do not stain, so upkeep is cheaper.

-

Raw aluminum profiles need more care to stop rust, especially outside.

-

Thicker profiles cost more but hold more weight and last longer.

-

Modular systems with t-slot or v-slot profiles are easy to fix or upgrade, saving money over time.

Aluminium profile manufacturers often say to use anodized aluminum for tough jobs and low care. Architectural aluminum extrusions with anodized surfaces last longer and look good with little work. Picking the right alloy, finish, and thickness gives the best mix of cost, strength, and long life for any design.

Tip: Architects should choose the profile type, alloy, and finish that fit the project. Anodized aluminum profiles give the best mix of strength, style, and easy care for most new buildings.

Applications in Architecture

Facades and Windows

Architectural aluminium profile is important for building facades and windows. Designers use these profiles to make thin, strong frames. These frames hold big glass panels. More light comes into buildings because of these frames. The look is clean and modern. Many commercial and home projects use architectural aluminum extrusions. These profiles are flexible for many uses. Anodized finishes protect the surface. They help the frames stay bright for a long time. Aluminium profile manufacturers make many shapes and sizes. This helps fit different windows and facades. Architects pick these profiles because they resist weather. They are also easy to take care of.

Tip: Pick profiles with thermal breaks for energy savings. These help keep rooms warm or cool.

Load-Bearing Structures

Some building jobs need strong support. Structural frames made from architectural aluminium profile are strong but not heavy. Builders use these profiles for curtain walls, canopies, and roofs. 6061 and 6005 alloys are good for holding weight. They do not bend or rust easily. Aluminium profile manufacturers make safe extrusions. These profiles help make safe schools, offices, and public places.

A table below shows common load-bearing applications:

|

Application |

Alloy Used |

Benefit |

|---|---|---|

|

Curtain Walls |

6061 |

High strength |

|

Roof Structures |

6005 |

Lightweight, durable |

|

Canopies |

6061 |

Corrosion resistance |

Decorative and Modular Uses

Architectural aluminium profile is used for decoration and modular parts. Designers use these profiles for walls, railings, and furniture. T-slot and v-slot profiles are easy to put together and change. These uses help architects make flexible rooms in homes and offices. Many aluminium profile manufacturers have modular systems for different designs. Special finishes add color and texture inside.

Note: Modular uses save time and money when building or changing things.

Architectural aluminum extrusions help mix style and strength. Many new buildings use these profiles for both looks and support.

Choosing the Right Aluminum Extrusions

Assessing Project Needs

Each building project is different. Architects and builders check what each part must hold. Heavy frames need strong aluminum extrusions, like 6061 alloy. Lighter parts can use 6063 alloy. The place where the building is matters too. Wet or salty air needs profiles that do not rust. Anodized finishes help protect aluminum in these places.

Modern spaces need flexible designs. Some projects need custom aluminum extrusions for special shapes or sizes. Other projects use standard profiles to build faster. Architects pick profiles that match the style they want. Smooth finishes and thin frames make a modern look. The budget is important too. Thicker profiles and special finishes cost more. But they last longer and need less care.

Tip: Write down the main things your project needs. Think about strength, weather, design, and cost before you choose aluminum extrusions.

Sourcing and Quality Tips

Getting good aluminum extrusions starts with trusted suppliers. Aluminium profile manufacturers with a good history give better quality. Always ask for samples before you order a lot. Check if the surface is smooth and the color is even. Good suppliers give test reports that show how strong their aluminum extrusions are.

A simple checklist helps when talking to suppliers:

-

Ask for proof of quality, like ISO certificates.

-

Ask for details about the alloy and finish.

-

Compare prices, but do not pick just the cheapest.

-

Make sure the supplier can deliver on time.

Designs are more flexible when suppliers have both standard and custom aluminum extrusions. Good aluminium profile manufacturers help fix problems and answer questions fast. They also give advice on the best profiles for each design.

Note: Good aluminum extrusions save time and money. They help buildings stay strong and look nice for many years.

Picking the best architectural aluminium profile means thinking about strength, finish, and what the project needs. 6063 alloy with anodized finishes is good for facades and windows because it looks nice and lasts long. If you need strong frames, use 6061 or 6005. Slim, modular profiles work well for decorations and flexible designs.

-

Architects should:

-

Solve hard problems early in the design.

-

Talk with aluminium profile manufacturers to find better answers.

-

Use surface treatments to make profiles look better and last longer.

-

Try out designs with models before making a lot.

When you match technical needs with design ideas, you get strong and good-looking architectural aluminum extrusions that last.

-

English

English  français

français  Deutsch

Deutsch  русский

русский  español

español  português

português  العربية

العربية  Melayu

Melayu  ไทย

ไทย  Indonesia

Indonesia  हिंदी

हिंदी

Rangkaian IPv6 disokong

Rangkaian IPv6 disokong